Cube Ice Machine With Automatic 1400P 2000P 2400P

Product Introduction

Ice machines have revolutionized the way we produce and consume ice. From small-scale residential use to large-scale industrial operations, ice machines are indispensable in various sectors. In this blog post, we will explore industrial ice machines and their role in the food and beverage industry, as well as discuss some factors to consider when choosing the right machine for your business.

Industrial ice machines are specifically designed to cater to the high-demand needs of businesses in the food and beverage industry. These machines are capable of producing large volumes of ice rapidly, ensuring a constant supply for commercial use. Whether you run a restaurant, bar, or catering service, having a reliable and efficient industrial ice machine is crucial to meet customer demands.

When selecting an industrial ice machine, several factors should be taken into consideration. Firstly, the production capacity of the machine should align with your business's ice consumption requirements. It is essential to invest in a machine that can keep up with demand without compromising on quality. Opting for a machine with a modular design allows for scalability, enabling your business to expand its ice production capacity as needed.

Another crucial consideration is the type of ice produced by the machine. Different businesses might have specific requirements, such as cubed ice, flaked ice, or crushed ice. Understanding your business's needs and the characteristics of each ice type is vital in making an informed decision.

Furthermore, energy efficiency is a significant factor when choosing an industrial ice machine. Look for machines that are designed to minimize water and energy consumption. Not only will this help reduce operational costs, but it also contributes to sustainable and environmentally friendly practices.

Maintenance and servicing should not be overlooked when selecting an industrial ice machine. Regular cleaning and upkeep are essential to ensure the longevity and optimal performance of the machine. Some machines come with advanced features such as self-cleaning mechanisms, which can streamline maintenance processes and save valuable time and effort.

In conclusion, industrial ice machines play a significant role in the food and beverage industry by ensuring a consistent supply of ice for commercial use. Selecting the right machine involves considering factors such as production capacity, ice type, energy efficiency, and maintenance requirements. By investing in a reliable and efficient industrial ice machine, businesses can meet customer demands while optimizing operational costs and sustainability.

| Model No. | Daily capacity (kgs/24hours) | Ice storage bin capacity (kgs) | Input power (Watt) | Standard power supply | Overall size (LxWxH mm) | Available cube ice size (LxWxH mm) |

| Integrated Type (Built-in ice storage bin, standard cooling type is air cooling, water cooling is optional) | ||||||

| JYC-90P | 40 | 15 | 380 | 220V-1P-50Hz | 430x520x800 | 22x22x22 |

| JYC-120P | 54 | 25 | 400 | 220V-1P-50Hz | 530x600x820 | 22x22x22 |

| JYC-140P | 63 | 25 | 420 | 220V-1P-50Hz | 530x600x820 | 22x22x22 |

| JYC-180P | 82 | 45 | 600 | 220V-1P-50Hz | 680x690x1050 | 22x22x22/22x11x22 |

| JYC-220P | 100 | 45 | 600 | 220V-1P-50Hz | 680x690x1050 | 22x22x22/22x11x22 |

| JYC-280P | 127 | 45 | 650 | 220V-1P-50Hz | 680x690x1050 | 22x22x22/22x11x22 |

| Combined Type (Ice maker part and ice storage bin part were separated, standard cooling type is water cooling, air cooling is optional) | ||||||

| JYC-350P | 159 | 150 | 800 | 220V-1P-50Hz | 560x830x1550 | 22x22x22/22x11x22 |

| JYC-400P | 181 | 150 | 850 | 220V-1P-50Hz | 560x830x1550 | 22x22x22/22x11x22 |

| JYC-500P | 227 | 250 | 1180 | 220V-1P-50Hz | 760x830x1670 | 22x22x22/22x11x22 |

| JYC-700P | 318 | 250 | 1350 | 220V-1P-50Hz | 760x830x1740 | 22x22x22/29x29x22/22x11x22 |

| JYC-1000P | 454 | 250 | 1860 | 220V-1P-50Hz | 760x830x1800 | 22x22x22/29x29x22/40x40x22 |

| JYC-1200P | 544 | 250 | 2000 | 220V-1P-50Hz | 760x830x1900 | 22x22x22 |

| JYC-1400P | 636 | 450 | 2800 | 380V-3P-50Hz | 1230x930x1910 | 22x22x22/29x29x22/22x11x22 |

| JYC-2000P | 908 | 450 | 3680 | 380V-3P-50Hz | 1230x930x1940 | 22x22x22/29x29x22/40x40x22 |

| JYC-2400P | 1088 | 450 | 4500 | 380V-3P-50Hz | 1230x930x2040 | 22x22x22 |

PS. The voltage of ice machine could be customized, such as 110V-1P-60Hz.

Please feel free to contact us if you need larger capacity of ice machine, such as 2/5/10 tons ice machine etc.

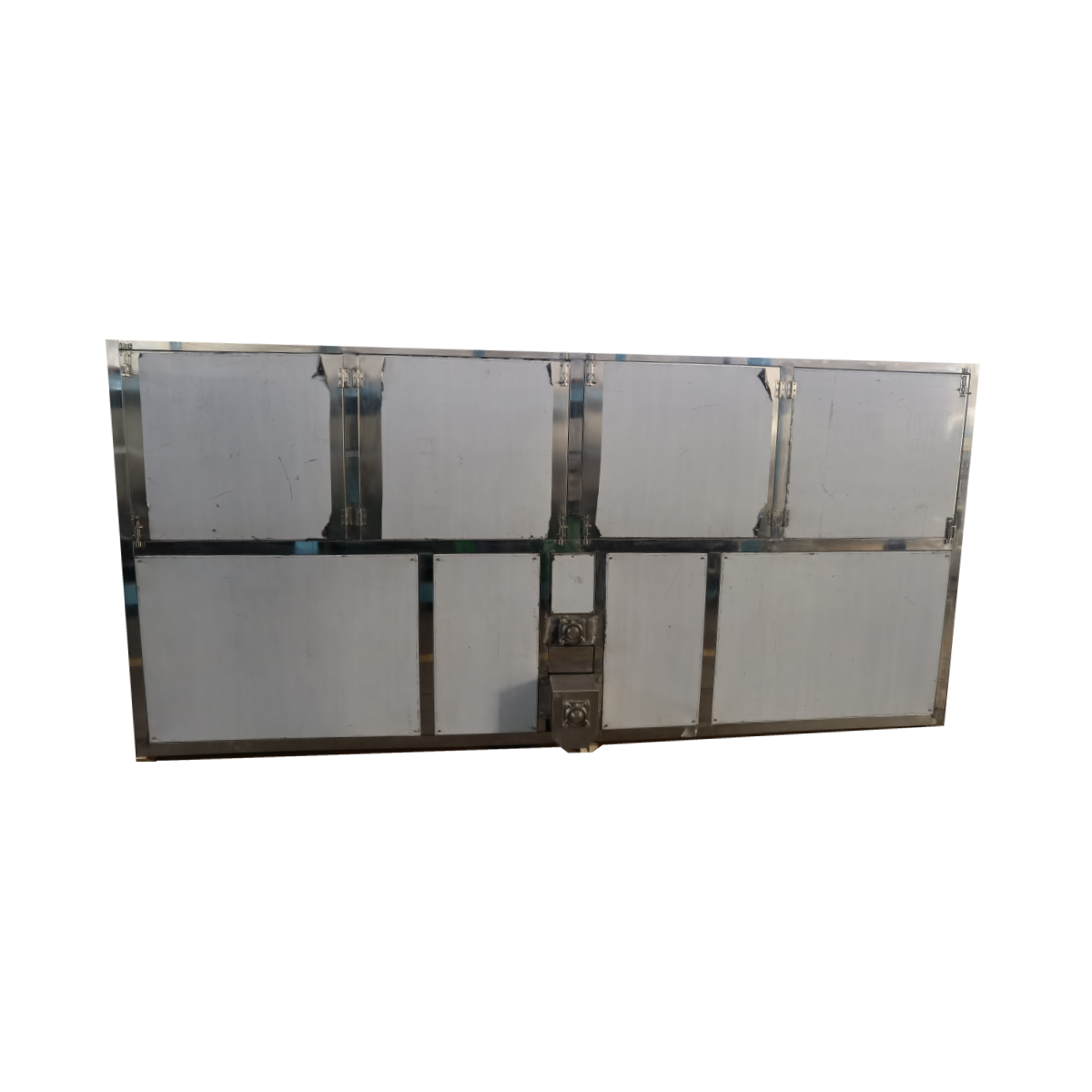

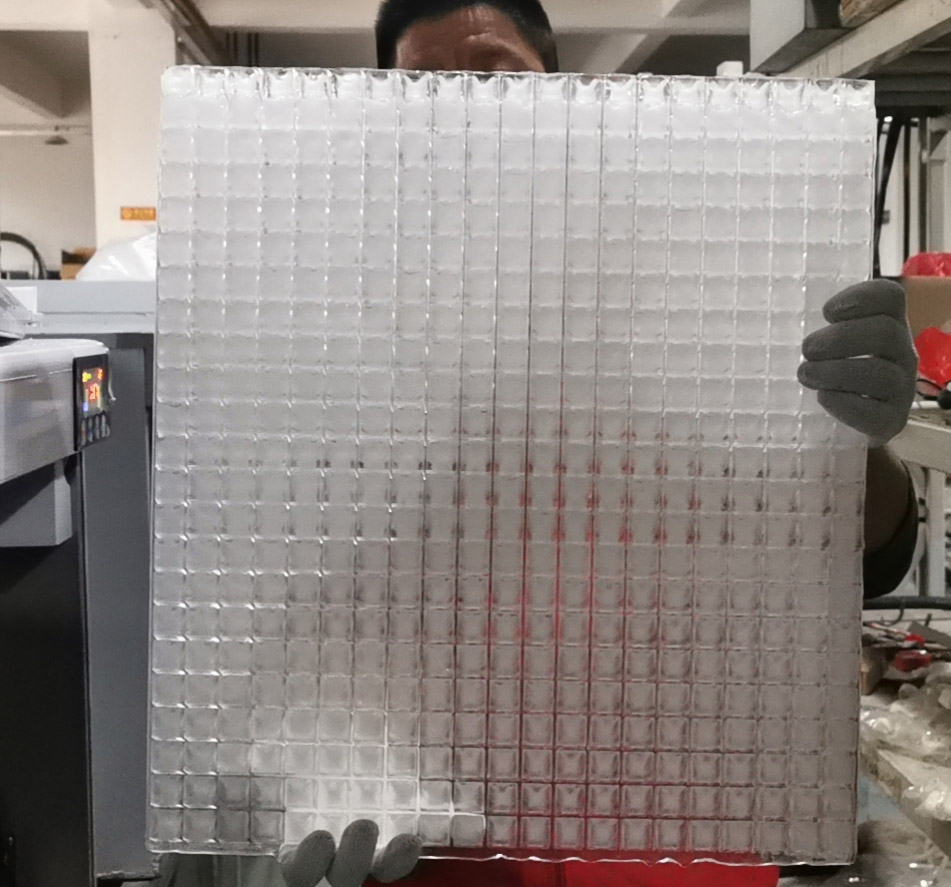

Product Display

Feature

1. Large size cube ice

2. Slow melting rate cube ice

3. Providing maximum cooling

4. Reducing ice consumption

5. Saving costs

6. Suit for ice bagging and dispensing

7. Widely use

8. Imported parts

Working Principle

Cube ice machines freeze water in batches. Those with vertical evaporators have a water dispensing tube at the top that creates a waterfall effect. As the water flows into and out of each cell in the evaporator more is frozen until the cells fill with completely frozen ice.Once the ice is ready to drop, the ice machine goes into a harvest cycle. The harvest cycle is a hot gas defrost, which sends hot gas from the compressor to the evaporator. A hot gas cycle defrosts the evaporator just enough to release the cubes into the ice storage bin (or ice dispenser) below.