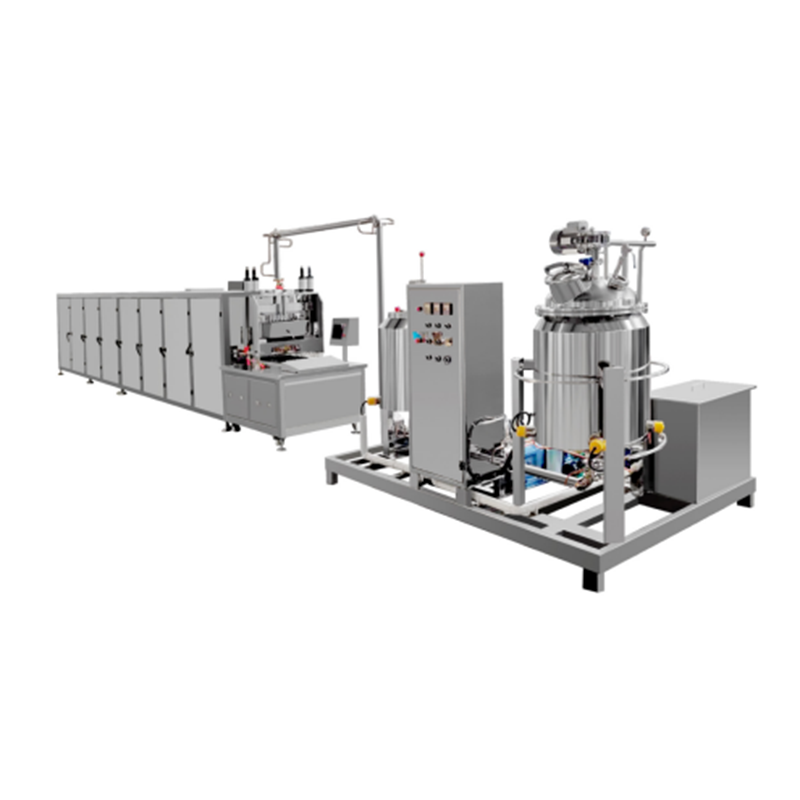

lollipop Candy Making Machine

Features

Introducing our innovative and efficient hard candy making machines, which are designed and manufactured to meet the stringent requirements of GMP standards. The machine adopts the latest hygienic structure to ensure the hygiene and cleanliness of the whole candy making process.

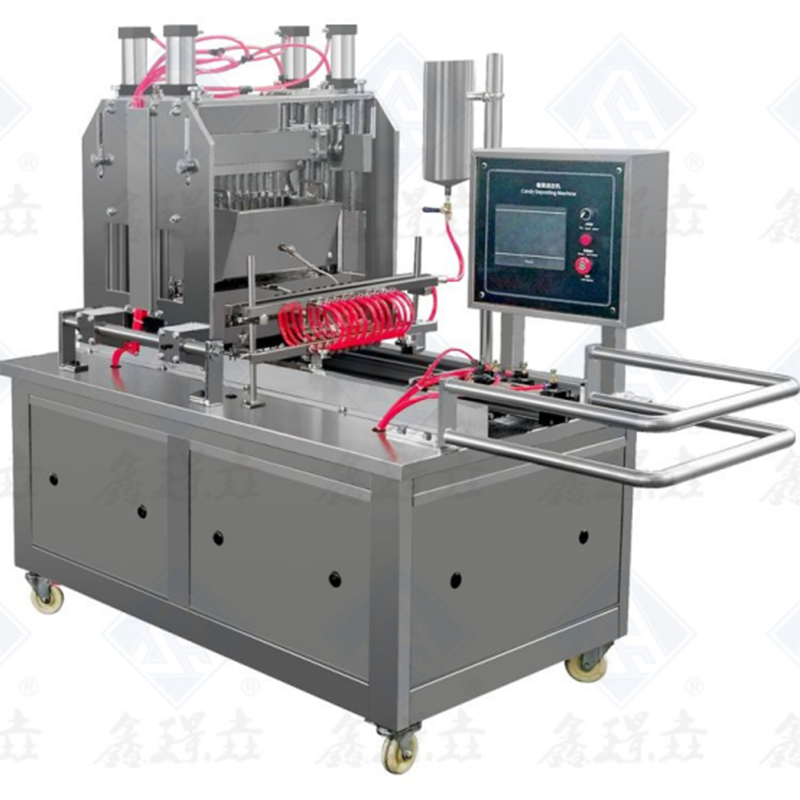

Our hard candy making machines are equipped with advanced PLC programmable process control, which provides precise temperature and time control for candy sous-vide cooking, as well as depositing temperature and speed control. This results in consistent, high-quality candy every time.

Operating this machine is a breeze thanks to the user-friendly LED touch screen. The screen displays the entire process flow, allowing the operator to monitor and adjust settings as needed. With just a few simple touches, anyone can easily operate our machines, even without extensive training.

Shanghai Jingyao Industrial Co., Ltd., we understand the importance of efficiency in confectionary production. That's why our hard candy makers can dose and mix ingredients such as flavors, colors and acid solutions in one streamlined process. This saves time and energy, increasing productivity.

With our machines, you can rest assured that your candy releases will be flawless. Conveyor chain, cooling system, and double demoulding devices cooperate seamlessly to ensure consistent and smooth demoulding of various shapes of candies. Whether you want round candies, heart-shaped candies, or any other custom shape, our machines have you covered.

As a leading manufacturer in the food machinery industry, Shanghai Jingyao Industrial Co., Ltd. prides itself on providing high-quality machinery to increase productivity and efficiency in the food production process. With years of experience and expertise, we have become a trusted name in the industry. Our hard candy making machines are just one part of our commitment to provide our customers with cutting edge technology and reliable performance.

Choose our hard candy making machines and experience the difference in candy production. Contact us today to learn more about this innovative machine and how it can revolutionize your confectionery process.

| Production capacity | 150kg/h | 300kg/h | 450kg/h | 600kg/h | |

| Pouring Weight | 2-15g/piece | ||||

| Total power | 12KW / 380V Customized | 18KW / 380V Customized | 20KW / 380V Customized | 25KW / 380V Customized | |

| Environmental requirements | Temperature | 20-25℃ | |||

| Humidity | 55% | ||||

| Pouring speed | 40-55 times/min | ||||

| Length of production line | 16-18m | 18-20m | 18-22m | 18-24m | |