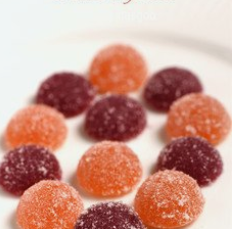

High Quality Pectin Jelly Candy Depositing Machine

Features

Why choose us

● Diversified solutions, we will provide customers with diversified and personalized solutions based on customer needs, project conditions, and different regions.

● Possess core technology, independently develops and manufactures candy production lines, supplying world-renowned candy brands and Chinese local candy brands.

● We have a professional installation and maintenance team. When customers need help, they can go to the scene to solve various candy production machine problems.

What are the benefits of Pectin Jelly Candy Depositing Machine

● Production of high quality Jelly Candy

Without a doubt, the biggest reason to buy a Jelly Candy Making Machine is to make the best and most ideal Toffee we can.

● Increase output

Jelly Candy Making Machine increases your output by maximizing your output.

Short machine downtime benefits the production process.

This increases your sales, which in turn increases profits.

● Save cost and time

Toffee lines are usually fully automatic.

More labor cost and time cost can be saved.

● Easy to clean and maintain

The Jelly Candy Making Machine and sugar making equipment produced by Jingyao Machinery are made of high quality materials, carefully designed and researched for a long time.

Simple maintenance and easy cleaning.

● Easy to use

Most of our Jelly Candy Making Machines are fully automatic production controlled by computer to minimize the consumption of human resources.

And easy to use, requiring less training to operate.

● Multifunctional process

Hard candy production equipment and hard candy production lines produced by Jingyao can produce many types and styles of hard candy.

| Production capacity | 150kg/h | 300kg/h | 450kg/h | 600kg/h | |

| Pouring Weight | 2-15g/piece | ||||

| Total power | 12KW / 380V Customized | 18KW / 380V Customized | 20KW / 380V Customized | 25KW / 380V Customized | |

| Environmental requirements | Temperature |

20-25℃ |

|||

| Humidity |

55% |

||||

| Pouring speed |

30-45 times/min |

||||

| Length of production line | 16-18m | 18-20m | 18-22m | 18-24m | |