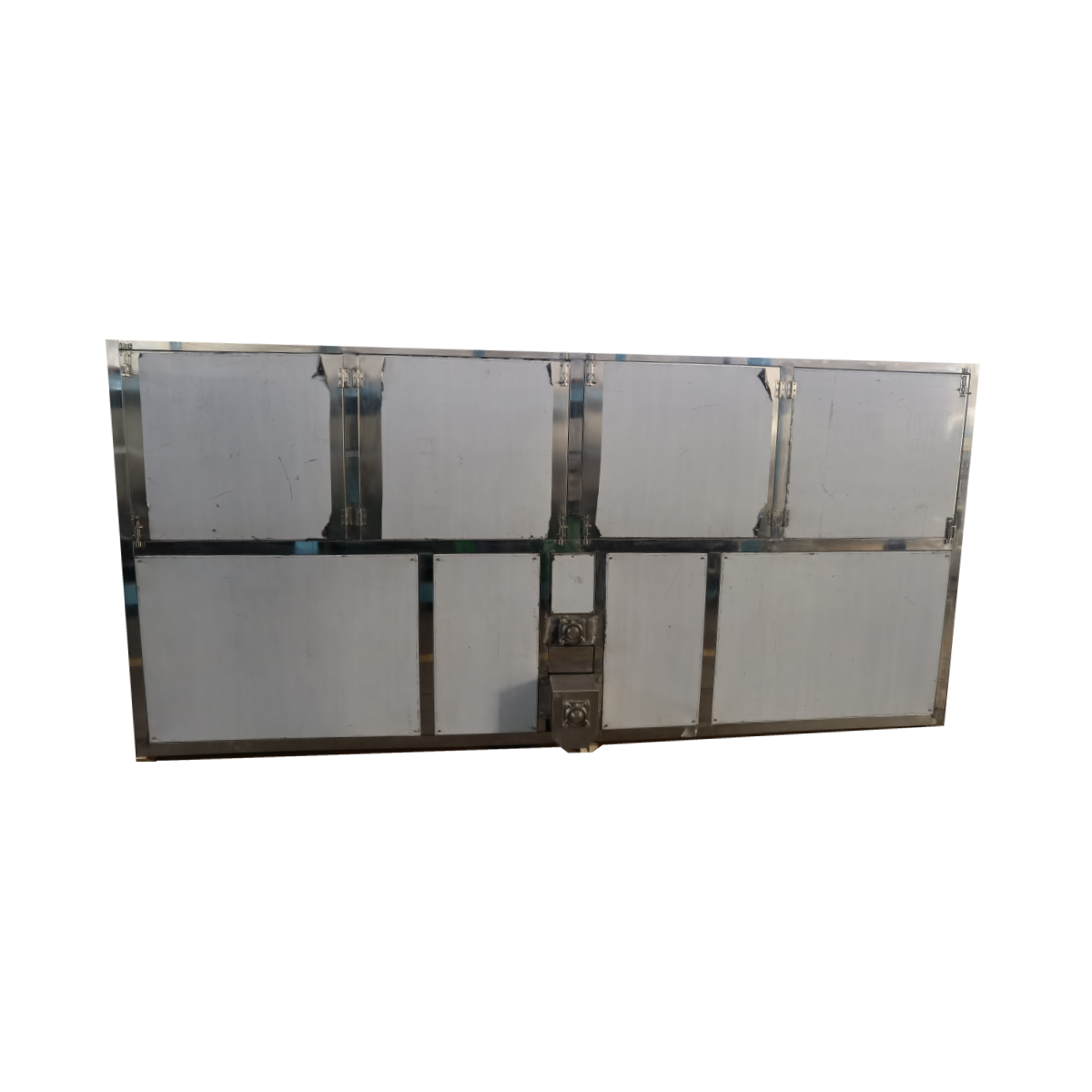

Large capacity industrial fresh water flake ice machine

Product Introduction

Flake ice machine is suitable for fish preservation, poultry slaughter cooling, bread processing, printing & dyeing chemical, fruit and vegetable preservation, etc.

It has fresh water flake ice machine and seawater flake ice machine.

Advantages of flake ice

1)As its flat and thin shape, it has got the largest contact area among all types of ice. The larger its contact area is, the faster it cools other stuff.

2)Perfect in food cooling: flake ice is type of crispy ice, it hardly forms any shape edges, in food cooling process, this nature has made it the best material for cooling, it can reduce the possibility of damage to food to the lowest rate.

3)Thoroughly mixing: flake ice can become water quickly through the rapid heat exchanging with products, and also supply the moisture for products to be cooled.

4)Flake ice low temperature:-5℃~-8℃; flake ice thickness: 1.8-2.5mm, can be used directly for food fresh without ice crusher any more,saving cost

5)Fast ice making speed: produce ice within 3 minutes after turn on. It take off ice automatically.

|

Model |

Capacity(ton/24hours) |

Power(kw) |

Weight(kgs) |

Dimensions(mm) |

Storage bin(mm) |

|

JYF-1T |

1 |

4.11 |

242 |

1100x820x840 |

1100x960x1070 |

|

JYF-2T |

2 |

8.31 |

440 |

1500x1095x1050 |

1500x1350x1150 |

|

JYF-3T |

3 |

11.59 |

560 |

1750x1190x1410 |

1750x1480x1290 |

|

JYF-5T |

5 |

23.2 |

780 |

1700x1550x1610 |

2000x2000x1800 |

|

JYF-10T |

10 |

41.84 |

1640 |

2800x1900x1880 |

2600x2300x2200 |

|

JYF-15T |

15 |

53.42 |

2250 |

3500x2150x1920 |

3000x2800x2200 |

|

JYF-20T |

20 |

66.29 |

3140 |

3500x2150x2240 |

3500x3000x2500 |

We also have larger capacity of flake ice machine, such as 30T,40T,50T etc.

Working principle

Flake ice machine working principle is heat exchange of refrigerant. Outside water flows into the tank, then pumped into the water distribution pan by water circulating pump. Driven by the reducer, the water in the pan evenly flows down the inner wall of evaporator. The refrigerant in the refrigeration system evaporates through the loop inside the evaporator and absorbs large amount of heat by exchanging heat with the water on the wall. As a result, the water flow over the surface of inner evaporator wall sharply cools down to below the freezing point and freezes into ice instantaneously.When the ice on the inner wall reaches a certain thickness, spiral blade driven by reducer cut the ice to piece.Thus ice flake forms and falls into the ice storage bin under ice flakers, stocking for use.The water not turning into ice will drop in the water baffle at the bottom of evaporator and flow into the water tank for recycling.